Experimental platform for marine VAV air conditioning systems

1. Brief introduction

The experimental platform of marine VAV air conditioning system consists of a direct expansion VAV air conditioning system and a set of data acquisition and monitoring system. VAV air conditioning system consists of air supply system equipped with VAV terminal and direct expansion (DX) refrigeration unit for cooling and dehumidification of air. The test bench includes variable capacity refrigeration compressor, electronic expansion valve, thermal expansion valve, water-cooled condenser, air treatment box, pressure independent VAV terminal, variable frequency fan, supply air static pressure control unit, new/return air valve, programmable controller, Angilent data acquisition instrument, Yokogawa power meter and a series of high-precision temperature, humidity, pressure and wind speed sensors. The parameters on the refrigerant side of the test-bed, such as evaporation / condensation temperature, suction / exhaust pressure and superheat, and the parameters on the air side, such as supply air static pressure, supply air temperature, air valve opening, cabin temperature / humidity, as well as the speed of compressor and fan, can be collected, monitored and analyzed in real time.

2. System diagram of the platform

3.Researches concerned

1) A general dynamic thermodynamic system model based on component model for marine direct expansion VAV air conditioning system is established for accurately describing the steady-state and dynamic characteristics of the system.

2) The operation characteristics and energy saving of marine direct expansion VAV air conditioning system are investigated by means of simulation and experiment.

3) The control strategy and control method of marine direct expansion VAV air conditioning system are studied to realize good independent control of cabin air quality.

Relevant researches can lay a foundation to the application and promotion of VAV air conditioning technology in ships and promote ship energy conservation.

Test rig for propulsion systems powered by fuel cells

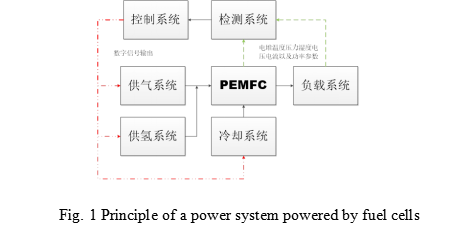

1. BriefIntroduction

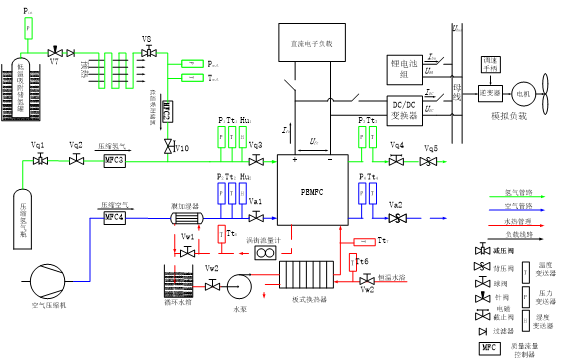

Thetestrigmainly consistsof fourparts, which include fuel cell system, energy storagesystem, simulated load and monitoring sections. The fuel cellsystem hasa 5kW fuel cell unit and a DC / DC converter. The energy storagesystem iscomposed of 48V/200Ah lithium batteries. The simulated load is divided intoadynamometer and propulsion motor simulated load device, in which the dynamometer is 6kW programmable DC electronic load, and the propulsion motor simulated load device is composed of 7.5kW DC brushless motor and 10kW dynamometer. The monitoringsystem is used to collect experimental data, fuel cell alarm and control variables such as gas flow rate andload. The monitoring unit adopts LabVIEW to realize communicationby controlling viaPLC, DAQ, serial port, and SCPI modules. Each subsystem is relatively independent, that is, the control optimization of each link of the system can be carried out separately, and the EMS research of multi-energy system can also beperformed.

2. Schematic show of the test rig

3. Researches carried out

1) The performance and fault diagnosis of a fuel cell system. Based on fuel cell subsystem, firstly, the influence of gas flow rate, pressure and humidity at the anode and anion inlets ofthefuel cell can beanalyzed, and the mathematical model of thefuel cell system can be established. Secondly, the multi-coupling variable optimization researchfor water vapor, heat and gas management of proton exchange membrane fuel cell can beperformedby considering the effects of the gas state at the each flow inlet, reactor cooling water and load change.Finally, the model of fault diagnosiscan be established by single cell voltage monitoring system.

2) Research onenergymanagement ofelectricpowered propulsionsystem forgreenships. Based on the operation conditions oftypical cruise ships, the energy management system of DCelectricpropulsionships and the control strategies can be optimized to improve the service life ofthemain power supply and the stability ofan electricpropulsionsystem.

3) Verificationexperiments for different hydrogen storage systems. Fuel cells are combined to provide abundant operating conditionsfor thesimulationof different hydrogen storage systems andfor theexploration offeasibility ofhydrogen releasing that can matchthe simulated operating conditions.

Test rig for developing storage systems by adsorption of fuel gases (hydrogen, methane) under high pressures

1. Brief introduction

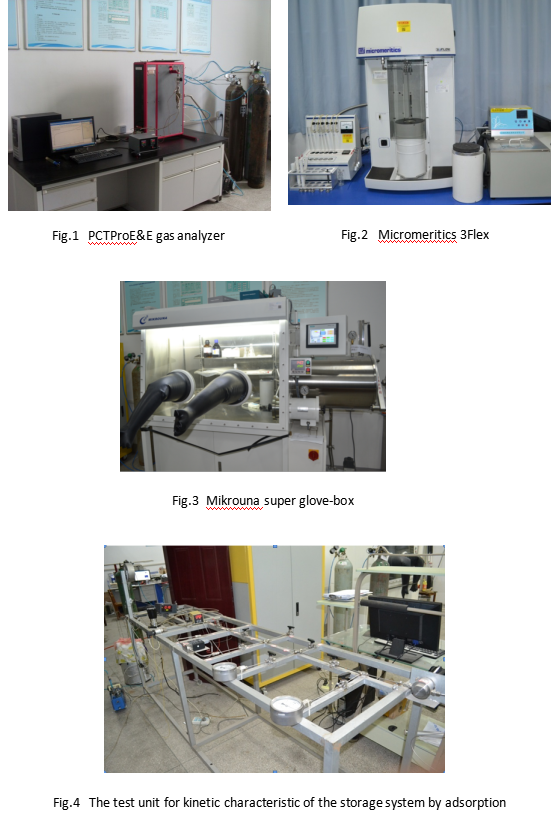

The test rig was constructed forthe development of suitable adsorbents andtheir storage system for onboard storage of natural gas and hydrogen by adsorption. The test rig can be separated into two parts, one part is for measuring adsorption equilibrium data and the other is for evaluating the kinetic characteristic of adsorption of fuel gases on the adsorbents. The main instruments currently available includePCTPro-E&E gas sorption analyzer,Micromeritics 3Flex, Mikrouna Super Glovebox etc.

Researches have been comprehensively performed theoretically and experimentally for the techniques relevant to thestorage of such fuel gases as hydrogen andnatural gas by adsorption. The researches carried out also include the molecular simulations andnumerical simulations for developing high performance adsorbents suitable for onboard applications. About 15 projects, which include twofinancially supported by national natural science of China, have already conducted so far, and there are more than 120 research papers, five patents have beenpublished.

2.Schematic show of the rig

Main instruments for the rig are shown in Figs.1-3, and bothPCTProE&E gas sorption analyzer and Micromeritics 3Flex were volumetrically developed. Those schematically shown in Fig.4 was specially designed for the development of thesuitable adsorbents in terms ofkinetic characteristic of fuel gases on the storage system by adsorption.

3、Researches carried out

1) Development of MOFs based adsorbents for adsorbed natural gas(ANG);

2) Development of MOFs based and carbonbased adsorbents for onboard hydrogen storage by adsorption;

3) Development of MOFs composite for hydrogen storage based on the nano-confinement by theincorporation ofcarbon based materials and the spillover of hydrogen molecules by loading the transitionalmetals;

4) Optimization of the structure and heat conducting enhancement measures for the pressurized vessel containing hydrogen under low temperatures and high pressures.

Testrig for new refrigerants and heat pumpsworking at high temperatures

1. Briefintroduction

The testrig shown in Fig.1consists of a refrigerating/heating unit, a set of hot and cold water temperature/flow control device,related data acquisition and monitoring system. The test platform comprises a refrigeration compressor, an electronic expansion valve, a manual throttle valve, an evaporator, a condenser, a spray cooling control device, a condensate tank, an evaporation tank, a chilled water pump, a condensate pump, a SCR heater, a programmable controller, an Angilent data acquisition device, a Yokogawa power meter and a series of high-precision temperature, pressure and flow sensors. The parameters of refrigerant side, such as evaporation/condensation temperature, suction/exhaust pressure, superheat, and the parameters of water side, such as flow rate, temperature and pressure can be collected, monitored and analyzed in real time.

3. Researches carried out

1) Development ofnew environmentally friendly refrigerants. The refrigerant composition with low GWP is studied, and the new refrigerant of zero ODP inhibiting global warming is developed. In particular, refrigerants with following properties are underdeveloped: having similar cycle performance as HFC-134a and HCFC-R22;potential substitutes for HFC-134a and HCFC-R22.

2) Study on Characteristics of High Temperature Heat Pump Systems. The cycle characteristics of high temperature heat pump system under different operating conditions such as different condensation temperatures, different evaporation temperatures and different superheats are investigated and analyzed. The cycle characteristics concerned include working pressure, unit volume heating capacity and heating coefficient.

Research platform for adsorption refrigeration powered by waste heat on ships

1. Brief introduction

The platform consists of two major parts, one is the test rig for evaluating the performance of the adsorbate foradsorption refrigeration, the other is for researching the method for comprehensively utilizing the cooling capacity generated by adsorption refrigeration unit powered by waste heat on ships.

Volumetric method was employed to set up the test rig for evaluating the performance ofthe adsorbate.Data Acquisition instrument FLUKE2620A, mechanical vacuum pumpZX-1, pressuretransducer MPM4730,thermostat Bilon GDH-4006 andSC-15,Electric vacuum drying ovenDZF-6020 and steam generator MDY-3.5 were equipped on the rig.

The platform forstudying the cooling capacity was co-developed byincorporating with Wuhan Yunhe Dingyu Refrigeration Technology Company. The platform have fiveXF-ZQ-12-3D adsorbers for refrigeration powered by low pressure steam, the evaporating temperature of the ammonia contained within the adsorbers can normally be kept below-28℃. The cooling capacity supplied bythe platform cansimultaneously maintain the temperature of an onboard cooling store in volume about18m3 at -18℃and8m2 air conditioning room at a normal temperature. The platform is suitable for implementing such researches as working pairs in adsorption refrigeration for onboard applications.

2. Schematic show of the platform

3. Researches carried out

1) The adsorbent suitable for working at high temperatures similar to those onboard ships;

2) The crucial factors influencing the cooling capacity of the adsorption refrigeration unit;

3) The crucial factors for performancedeterioration of the adsorbent for onboard application;

4) Thecontrolling strategy of an adsorption refrigeration unit for supplying cooling load for cooling stores and air conditioning rooms.